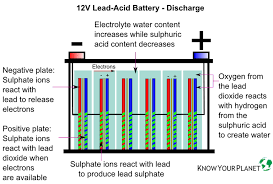

A lead-acid battery is made up of the following components, enclosed within a plastic or ebonite box or casing (see Figure 1) (UNEP, 2003). There are positive and negative terminals made of lead, which provide the connection points to external devices. There are sets of positive and negative plates kept apart by plate separators - porous sheets of PVC or polyethylene plastic, glass microfiber, or phenolic resins that allow the free movement of the ions in the electrolyte solution. The positive plates are grids made of lead or lead alloy coated with porous metallic lead paste, and the negative plates are lead grids coated with lead dioxide paste. A series of negative and positive plates plus separators makes up a battery element, and the battery elements are separated by plates of the same material as the battery box. The elements are bathed in a sulfuric acid electrolyte solution, which can be topped up via the plugs. In sealed batteries the electrolyte is either a gel or is soaked onto glass microfiber separators

Manually breaking up the batteries releases lead particles and lead oxide dust, which are a source of lead exposure to the worker (Suplido & Ong, 2000; UNEP, 2003). The dust and particles also settle in the surrounding soil and may be blown to more distant areas, contaminating the wider environment and becoming a source of exposure to the community (UNEP, 2003; Haefliger et al., 2009). Hammermills and shredders may release lead mist, which can dry and release lead dust if disturbed. Dust settled on vibrating equipment can become re-suspended in air and inhaled (OSHA, 2002).

During the separation process, water used in automated systems for separating lead from other components becomes heavily contaminated with lead compounds. If this leaks or is not treated before disposal it will contaminate the ground or soil. As this water evaporates it leaves a residue of fine lead dust that may then be dispersed by wind (UNEP, 2003). When lead components are moved around the recycling site, e.g. on open conveyor belts or in wheelbarrows, and when they are shovelled into the furnace, lead fragments and dust are released. The temperatures used for refining lead can be up to 1000 °C, which generates large amounts of lead fume. If the furnace is not under negative pressure or if the plant has inadequate ventilation and/or emission controls, the fumes will be inhaled by workers (UNEP, 2003). Lead fumes are particularly hazardous as the small particle size enables the lead to be inhaled into the lower respiratory tract and absorbed (ATSDR, 2007). The fumes will eventually settle as lead particles on surrounding surfaces and the soil, creating lead dust, which can also be inhaled. Fugitive lead emissions from these sources can be substantial and are more difficult to control. Sometimes ash from the smelting process is manually sifted to retrieve metal particles, dispersing lead-contaminated dust into the air (Paddock, 2016) Fume, lead particles and dust released at various stages in the recycling process will also settle on the skin, hair and clothes of workers. If workers do not wash and change clothes before returning home this lead becomes a source of take-home exposure to household members and even, potentially, to the wider community (Daniell et al., 2015). Lead poisoning in the spouses and children of lead workers, caused by transfer of lead from the workplace to home, has repeatedly been documented (Baker et al., 1977; Chisolm, 1978).

Informal lead recycling

Non-regulated, informal (“backyard” or “cottage”) recycling practices occur in many countries and have resulted in lead exposure and poisoning, with young children being particularly at risk (Matte, 1991; Suplido & Ong, 2000; Haefliger et al., 2009; van der Kuijp et al., 2013; Daniell et al., 2015). This practice is sometimes carried out in urban areas with high population densities, meaning that a recycling operation has the potential to affect a large number of people (Haefliger et al., 2009). There are few (if any) pollution controls. Lead-containing waste products, such as electrolyte solution and slag from the smelting process are often simply dumped, although slag may also be sold on for further smelting. The work may be carried out by small family groups around the home. Children often assist with dismantling the batteries and washing components (van der Kuijp et al., 2013). Because the recycling process is done with little knowledge of the toxicity of lead, and is conducted under poor conditions of safety, health and environmental controls, informal recycling is particularly likely to result

in environmental contamination and human exposure (UNEP, 2004; van der Kuijp et al., 2013; Daniell et al., 2015). Soil contaminated with lead compounds can spread throughout the community and be tracked into homes. If recycling activities take place around the home, then airborne lead can enter the home and accumulate on the floor, on beds and on other furniture (Haefliger et al., 2009). Settled dust can be re-suspended in the air and inhaled as people walk through or brush up the dust. Young children, who spend large amounts of time on the ground and who frequently put their hands and other objects in their mouths, are at particularly high risk of lead exposure in these settings. If the plastic components are inadequately washed before re-use for other products, then these products will be contaminated with lead (Manhart & Schleicher 2015). Battery casings may be used around the home as a construction material or as containers, again introducing the possibility of lead contamination (Daniell et al., 2015). There have been reports in Cameroon and other countries of lead scrap from informal recycling being mixed with scrap aluminium to make cooking pots (CREPD, 2015). Lead can leach out into food being prepared or stored in these pots (Weidenhamer et al., 2014; Weidenhamer et al., 2017).

Other chemicals released during recycling

While the focus of this document is on the release of lead, there are a number of other hazardous chemicals that can be released during recycling. In addition to the lead terminals and plates, batteries contain various plastics or hard rubber (ebonite) and the sulfuric acid electrolyte solution. The lead components may contain other elements such as arsenic, antimony, barium and cadmium (UNEP, 2003). These substances may form part of the waste and emissions generated at various stages of the recycling process. The rubber and plastic components may be burned rather than recycled, producing toxic gases, including sulphur dioxide, chlorine, dioxins and dibenzofurans (UNEP, 2003).

Studies of lead exposure from recycling lead-acid batteries

Recycling lead-acid batteries can result in significant occupational exposure to lead. Were et al. (2012) investigated a lead-acid battery recycling plant in Kenya and found elevated concentrations of lead in the air and elevated blood lead concentrations in workers. The study identified a number of weaknesses in work practices and control measures that resulted in excessive exposure

to lead. Examples included inadequate engineering controls (including poor ventilation systems) and inadequate personal hygiene measures (including lack of respiratory protection and failure to use washing facilities). Among workers involved in recycling lead-acid batteries there is often poor general awareness of the hazards of lead (CREPD, 2015).

A review of published literature on exposures from formal-sector lead-acid battery manufacturing and recycling plants in developing countries found that seriously elevated blood and airborne lead concentrations were common (Gottesfeld & Pokhrel, 2011). In workers involved in battery recycling the arithmetic mean blood lead concentration was 64 µg/dL, with a range of 37.7 to 112.5 µg/dL. This contrasted with data from developed countries where few workers had blood lead concentrations above 50 µg/dL and most were below 25 µg/dL (though even these concentrations are likely to result in adverse health effects – see section 3.2).

The review also found that high airborne lead concentrations were reported in recycling facilities, with a mean value of 367 µg/m3 . This is 7 times higher than the permissible exposure limit of 50 µg/m3 as an 8-hour time-weighted average (TWA) adopted in the USA (OSHA, 1978). Communities living near recycling facilities are at risk of exposure to lead, and extensive contamination of soil surrounding many formal sector recycling plants has been reported (Levallois et al., 1991; Wang et al,. 1992; Zhang et al., 2016). In their review, Gottesfeld & Pokhrel (2011) summarized 11 studies in seven countries on lead exposure of children residing near lead battery manufacturing and recycling facilities and reported an average blood lead concentration of 29 µg/dL, with values up to 71 µg/dL.

Recently a large recycling plant in the USA was closed down after it failed to meet emission controls and waste management standards. This plant was found to have contaminated the surrounding area with lead to a distance of 1.7 miles (California Environmental Protection Agency, 2015).

The case studies given below illustrate how environmental contamination caused by the recycling of used lead-acid batteries can result in severe lead poisoning in a community, which may continue even after recycling operations have stopped. The first case describes exposure to lead via reclamation of lead and lead compounds from discarded batteries, and the health consequences. The other two case studies show that closing down or moving battery recycling operations are not sufficient measures on their own to prevent human lead exposure.

Senegal

Between November 2007 and March 2008, 18 children died from an aggressive central nervous system disease of unexplained origin in a neighbourhood of Dakar in Senegal (Haefliger et al., 2009). One of the possibilities considered was lead intoxication, as the mothers of some of the children were engaged in the recycling of used lead-acid batteries. Informal lead recycling in the region had been taking place since 1995 and various lead compounds had accumulated in the sandy soil over time. Around October 2007, some local residents realised that the accumulated lead in the soil could be sieved and sold. They therefore started to collect lead-enriched soil in sacks, which they brought into the community, sometimes even inside their homes.

An investigative mission was sent to work with the local health authorities in investigating the deaths. For cultural reasons it was not possible to conduct autopsies and post-mortem testing on the children who had died and, therefore, the mission team focused their investigation on the siblings and mothers of the children. Another group of children and adults, who were living in the same community but apparently unrelated to the deceased children, were also investigated to evaluate the extent of lead intoxication in the area. In total 81 individuals were examined and tested and all were found to be poisoned, often severely, with lead. In the children blood lead concentrations ranging from 39.8 μg/dL to 613.9 μg/dL were found (levels above 45 μg/dL indicate potentially serious poisoning).

Environmental investigations found that homes and soil were heavily contaminated with lead. Lead concentrations in outdoor soil were up to 302 000 mg/kg and indoor concentrations were as high as 14 000 mg/kg. For comparison, the US EPA standard for soil in a children’s play area is 400 mg/kg and for other residential areas it is 1200 mg/kg (US EPA, 2001). The exposure pathway was most likely via inhalation and/or ingestion of the contaminated soil and dust in suspension as young children were playing on contaminated ground. This indicated that other inhabitants of the affected area (about 940 people, of whom 460 were children and adolescents) might also be poisoned with lead.

While the causes of death of the 18 children could not be confirmed, circumstantial evidence, including heavy environmental contamination and the high blood lead concentrations in siblings suggest that most, if not all, of the children died because of encephalopathy as a result of severe lead poisoning. To prevent further exposures the homes were cleaned and contaminated soil was removed and replaced with cleaner soil. A public awareness campaign was also carried out to encourage a change in recycling practices.

Dominican Republic

In Haina, Dominican Republic, a lead screening survey was carried out in 116 children living close to a lead-acid battery recycling smelter (Kaul & Mukerjee, 1999). Very high blood lead concentrations were found with a mean value of 71 µg/dL. Shortly afterwards the government closed down the recycling plant. Six months later a follow-up survey was conducted in 146 lead-poisoned children in the same community (Kaul et al., 1999). This found that although the blood

lead concentrations had reduced significantly, with a mean of 32 µg/dL (range 6 to 130 µg/dL), they were nevertheless still high. Only 9% of the children had blood lead concentrations below 10 µg/dL and 28% of the children had blood lead concentrations above 40 µg/dL. For comparison, a survey was also carried out in 63 children living in a nearby community, which had similar demographic characteristics but no smelter. Here the mean blood lead concentration was 14 µg/dL (range 20 to 99 µg/dL) and 42% of children had levels <10 µg/dL.

An environmental assessment found that, although the smelter had shut down, metallic scrap and mixed residual soil and solid materials were still scattered around. Some clean-up activities had begun during the time of visit; however, an assortment of waste materials remained at the site and continued to be a hazard to the neighbourhood. The authors concluded that although closing the battery recycling facility significantly lowered blood lead concentrations of children, the children were still exposed to lead through their environment (Kaul et al., 1999). In 2008 and 2009 some remediation activities were carried out to remove contaminated soil and educational sessions were given to local children to help minimize their exposure to lead dust and materials (Blacksmith Institute, 2009).

Viet Nam

Dong Mai village in northern Viet Nam has been a centre for recycling lead-acid batteries since the 1980s. A study in 2006–2007 found elevated exposures to lead, and efforts were subsequently made to move household recycling operations to an industrial zone 1 km outside the village. The zoning was formalised by 2010, though some home-based recycling continued in a few households. A study was subsequently carried out over a one-year period from December 2011 to assess lead exposure in children and environmental levels of lead (Daniell et al., 2015).

All 109 children tested were found to have elevated blood lead concentrations, ranging from 12 to >65 µg/dL, with 28% having concentrations >45 µg/dL. The blood samples were measured using the LeadCare analyser, and a sample of the higher results were rechecked using laboratory analysis of venous samples. This generally gave lower values, but of 24 retested samples 80% were still above 45 µg/dL. Higher blood lead concentrations were associated with home recycling or parents currently involved in recycling in the industrial zone.

Environmental investigations showed legacy soil contamination in areas where recycling had previously been carried out, with a mean lead concentration of 2500 mg/kg. In other areas soil levels were lower though still high, at a mean of 1000 mg/kg. By contrast, soil lead concentrations at the school were very low with a mean of 34 mg/kg. Surface lead contamination was tested in 11 homes and a mean value of 95 µg/cm2 was found, considerably higher than the US EPA standard for dust on household floors of 0.043 µg/cm2 (US EPA, 2001).

Higher concentrations were found in homes with active recycling compared with those where recycling was no longer carried out. In these latter homes the highest concentrations were found around washing areas and in some kitchen and living areas. This suggested take-home lead contamination, with washing done at home rather than at the workplace. While surface contamination with lead was lower at the school, though still high at 41 µg/cm2 , four sleeping mats were found to have lead contamination at a mean of 221 µg/cm2 . This suggested that children had brought lead to school on their shoes and clothing.

This program provides an entry path to a CNC profession and a great basis for anybody excited about pursuing our CNC certificate for faculty credit. They hold collectively your automobile and carry out very important functions aboard SpaceX rockets. CNC machining is arguably the one method to produce high precision precision machining metallic elements for engineering designs the world over.

ReplyDelete